Flameproof Motors

Flameproof Motors

ABM offers some of the most reliable electric motors on the market today. Made with safety and efficiency in mind, all of our products meet the requirements established by the National Fire Protection Association. We’re also certified by a number of top safety organizations, including FM, UL, and the Canadian Standards Association.

ABM particularly specializes in supplying and servicing flameproof motors. Our flameproof products are designed to enclose flares and sparks as soon as they’re generated, halting fires at the source and preventing explosions outside of the motor from occurring.

ATEX / IECEx Motors:

Theses series of motors are capable of withstanding pressure during an internal explosion so that such an explosion does not vent into the external atmosphere which could also be explosive. They are also designed to prevent the occurrence of sparks, arcs, or hot spots in service, which avoids any further risk of explosion.

General Technical Data

-

Rated Power

0.18~315kW

-

Poles

2P, 4P, 6P, 8P, 10P

Description

Applications and Classifications of Flameproof Motors

Any environment that contains vapor, dust, gas, and other flammable substances can pose hazards to workers who regularly operate electric motors. If an explosion happens inside a machine’s motor in such a flammable setting, it could trigger a greater explosion outside of it, threatening the entire workplace in the process.

Flameproof motors are built to contain very hazardous contents within the motor. By isolating these hazards from the surrounding environment, they protect workers and facilities alike from unwanted accidents that could derail operations while ensuring that production continues without a hitch.

Hazardous motors are classified into two separate classes that are used to establish the kind of motor best for particular environments:

- Class I: Areas with vapors, liquids, gases

- Class II: Areas with dust

- Class III: Areas with flammable fibers or lint

Each class also has a subgroup: A – G. Each group indicates how elements are affected when explosions occur. The labels are organized by the severity of the requirements within each specific motor design:

- Groups A – D: Classified under Class I, due to their vapor or gas form.

- Groups E – G: Classified under Class II, due to their dust form.

In addition to motor classes, hazardous locations are further classified into divisions:

- Division 1: Explosive elements almost always present on location.

- Division 2: Explosive elements inside operator-handled storage tanks or containers with potential of spillage or leakage in event of equipment malfunction.

ABM’s ATEX, IECEx Flameproof Motor Options

ABM has many hazardous location motors depending on each application’s needs. With every customer, we work to strike the perfect balance between safety and productivity. That’s why our ABM flameproof motors always meet international standards put in place by the CSA, ATEX, UL, and IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for use in Explosive Atmospheres).

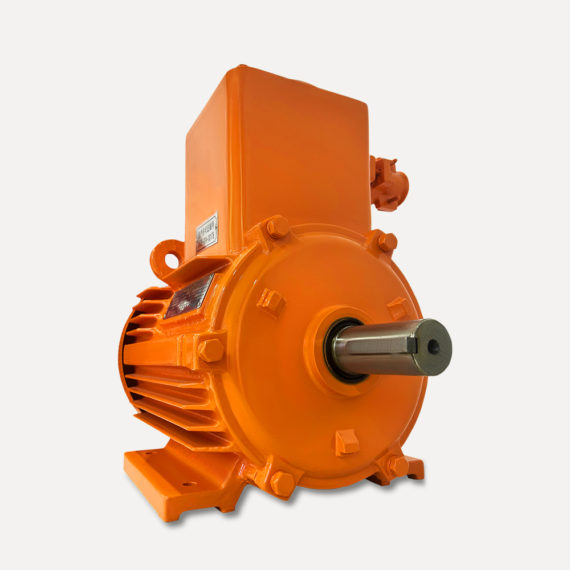

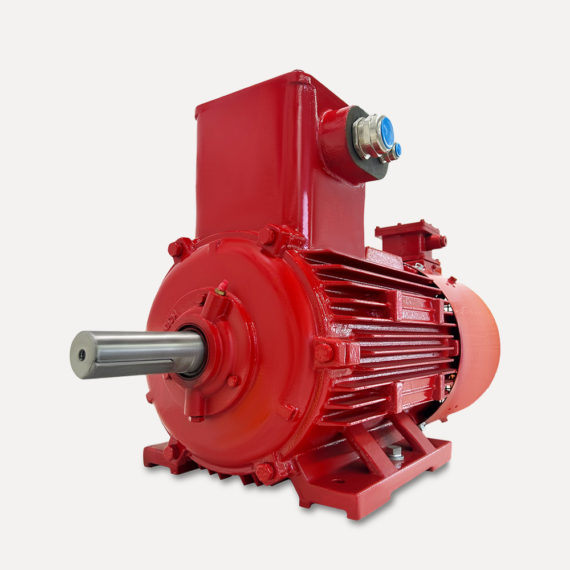

Below are just a few of ABM’s many flameproof motors:

Zone 1:

ATB – Wolong Nordenham GmbH Flameproof Motors

ATB released the first explosion-proof motor in 1952,. Specializing in low-maintenance and low-noise machines, it’s been a trusted producer of flameproof motors for more than six decades now.

Other Flameproof Products ATEX and IECex Supplied by ABM Include:

- Brook Crompton

- CEMP

- Elprom

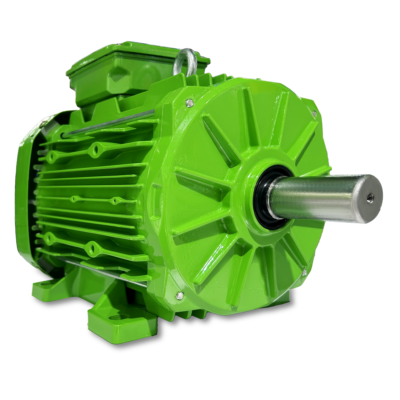

Zone 2:

- EEx nA Zone 2 by Brook Crompton

- EEx nA Zone 2 by Elprom

- EEx nA Zone 2 by CEMP

All of these motors are available in every NEMA/ IEC frame size, and all of them can be ordered with various mountings. We also provide single-phase motors at the customer’s request.